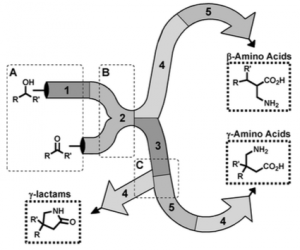

The Seeberger group have described a modular approach to continuous chemical processing allowing access to a variety of different structural classes. This, he demonstrates by the synthesis of APIs some of which went on to become “blockbuster” drugs.

So by appropriate combination of the modules, 2 – 5, containing the required reagent(s) you should be able to synthesise any one of the three structural classes shown from simple starting materials. This is a very neat idea indeed.

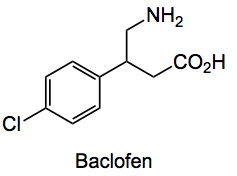

For example you need some Baclofen:

Module 1 has all the bits and reagents required to do the bleach oxidation of 4-chlorobenzyl alcohol. This product goes into module 2 where the Knovenagel takes place, modules 3, 4 and 5 carry out the conjugate addition of nitromethane, the hydrogenation and finally the hydrolysis to give the product in 65% overall yield and 10.3g or 48 mmol per day.

This modular approach is in dire need of scale-up, to pilot plant and production. Between 5 and 10g per day is obviously not enough material 50 – 100Kg is more realistic, and even that estimate is on the low side. Then there is the question of cGMP. The modules perhaps need to be dedicated, but that defeats the object of their interchangeability. Cleaning and avoidance of contamination may well turn into big issues. So lots of work still needs to be done to validate this sort of system. It may just be too costly to compete with a present day multipurpose system and batch processing. Small volume high margin drugs are the obvious place for this sort of continuous flow system, assuming the issues have been resolved. I have not mentioned safety aspects but I won’t go there.

The concept is great and I hope that some company somewhere is investigating something similar.

2,149 total views, no views today